Mixing process of Gilsonite

General Description of Gilsonite or "natural Asphalt" Mixing Process

Gilsonite or "natural Asphalt" Mixing Process – Natural Bitumen Benefits in Asphalt Paving Mixes

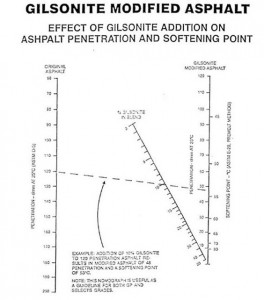

When Gilsonite or "natural Asphalt" is added to bitumen it modifies bitumen to lower its penetration, increase its viscosity and increases its softening point. For the manufacture of road paving mixes, Gilsonite increases the mixing stability, thus reducing shoving, rutting and other types of deformation problems that occur from heavy traffic and hot weather conditions. Gilsonite or "natural Asphalt" reduces the temperature susceptibility of most bitumen, thus achieving the high-temperature performance economically in low-temperature characteristics. Gilsonite or "natural Asphalt" is extremely easy to add, either to the paving mix directly or to the hot bitumen mix. It also causes minimal disruption of the contractor’s operation. The cost of Gilsonite or "natural Asphalt" is a small fraction of the cost of most other modifiers. Gilsonite or "natural Asphalt" easily combines with other hot mix components; forms stable solutions that do not separate during hot storage and using it does not require changes in pavement design, nor in the contractor’s standard pavement laying practices.

Generally speaking, gilsonite addition to bitumen gives three main results:

1. It lowers bitumen penetration

2. It increases bitumen viscosity

3. It increases the softening point

For the manufacture of road paving mixes, these are results of gilsonite addition:

Increases the mixing stability, thus reducing shoving, rutting and other types of deformation problems that occur from heavy traffic and hot weather conditions.

Reduces the temperature susceptibility of most bitumen, thus getting the high-temperature performance with little sacrifice in low-temperature characteristics.

Is extremely easy to add, either to the paving mix directly or to the hot bitumen. It also causes minimal disruption of the contractor’s operation.

Is a fraction of the cost of most other modifiers, roughly one-third the cost of Ethylene Vinyl Acetate (EVA) co-polymer or Styrene-Butadiene-Styrene (SBS).

Several other benefits are also obtained from the use of gilsonite modifier. These benefits can be important during manufacture and placement of hot mix pavements and often represent problem areas for polymeric modifiers. gilsonite:

Easily combines with other hot mix components;

Forms stable solutions that do not separate during hot storage;

Does not require changes in pavement design, nor in the contractor’s standard pavement laying practices

Gilsonite Mixing Process – Method addition

Gilsonite can be easily added to the hot mix in a variety of ways.

It can be pre-dissolved in hot bitumen prior to the addition of the bitumen to the mix.

It can be added directly to the asphalt mix in the batch plant or

It can be added directly to the asphalt mix in the drum mixer.

All three methods are discussed below. As a free-flowing, dry, granular solid, gilsonite can be added directly to small, pre-weighed, meltable plastic bags, or added in bulk using vein or screw feeders.

In one typical experience, gilsonite was added directly to the bitumen tank. The temperature of the bitumen was approximately 170°C and continuous recirculation through the top of the tank was used to create splashing action. The product dissolves easily with moderate mechanical agitation. Even faster dissolution can be obtained by using a mixer capable of generating a vortex.Furthermore, Gilsonite is readily combined and completely compatible with the other hot mix components and paving operations are virtually unaffected, i.e., no specialized equipment is required.

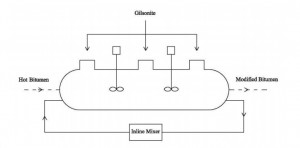

Technical Information – Gilsonite Mixing Process into Bitumen

This is a fairly simple procedure. A bitumen tank with a propeller stirrer with enough agitation action to create a vortex is recommended. The best choice is a “lightning” mixer or some other type of electrically powered mixer. An explosion proof motor is preferred if large dust concentrations are likely to occur. Gilsonite should be added slowly at the vortex. Provisions should be made to recirculate the hot bitumen through recirculation piping.

The most important item is that the minimum temperature should be about 170 to 175° C. Anything significantly less than this will extend mixing time. For typical (5-10%) substitution concentrations, 2-4 hours of mixing after the addition are completed should be sufficient. For master batch concentrations (over 10% Gilsonite) recirculation overnight is preferred.

Product used shall be crushed in mesh 30 to 50. The most important item is that the minimum temperature should be about 170 to 175° C. Anything significantly less than this will extend mixing time. For typical (5-10%) substitution concentrations, 2-4 hours of mixing after the addition are completed should be sufficient. For master batch concentrations (over 10% gilsonite) recirculation overnight is preferred. It is so obvious that percentage of gilsonite added to bitumen depends on initial bitumen specifications and features of desired product, but always between 5-18%.

If the bitumen cannot be heated higher than 170°C then you may consider using Selects other Grade (60/70mesh) or Selects Grade (200 mesh) rather than HMA Modifier Grade (175°C softening point) for modification. However, each one of these Selects grades will require slightly more Gilsonite to be added, relative to HMA Modifier grade, to achieve the same level of bitumen modification.

The dry gilsonite should be poured into the hot bitumen slowly. If it is added too fast then it may agglomerate, or “bal up” at the surface. If this happens then some manual stirring to disperse the agglomerations may be required. If a horizontal, cylindrical tank is used, then gilsonite should be added at an opening at the top (about 0.5-1.0 meters in diameter). Again, it should be poured in slowly and stirred with a mixer or a manual paddle so it does not “ball up” or agglomerate. Recirculation piping will be necessary to insure some agitation effect and proper dissolving.

Recirculation is very important to achieve proper dissolution. If mixing is done in a horizontal tank then it is essential that the gilsonite-modified bitumen be recirculating from the front of the tank to the back or vice versa. This should be accomplished, even if some re-plumbing of the tank is necessary, besides if an in-line mixer set in the recirculation line, then reaching for best degree of the mixture must be more successful.

Gilsonite does not dissolve instantly. Mixing a tank containing 10-15 MT bitumen and 5% Gilsonite addition will take about 2-4 hours to add in, and an additional 2-4 hours mixing time. Naturally, higher Gilsonite dosage levels will require longer mixing times.

Unfortunately, during mixing, there is no test or checklist to determine whether the gilsonite is blending well in the bitumen. However, if it is not, then large balls or chunks will be visible in the bitumen if it is in an open tank. Afterward, the best method to check whether gilsonite was fully mixed into the bitumen is by comparing the original and final penetrations of the bitumen.

This method requires that the original bitumen must be sampled and its precise penetration be determined. As it’s seen, the process is in the batch system. Cut off the line of feed and product indicates the batch system. The more recycle flow, better mixing. 3 hoppers design is better than 1 hopper because it causes the perfect distribution of gilsonite into the mixer.

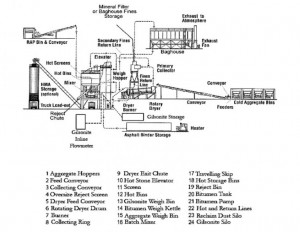

Gilsonite Mixing Process – Batch Plant (Pug Mill) Mixing

First, Gilsonite should be added during the dry cycle of the mixing procedure, onto the hot aggregate rocks, before the bitumen is added. We recommend extending the total cycle time by about 15 seconds to insure proper dissolution.

Chemical Mine World Gilsonite Company has found that 5 additional seconds of dry mixing and 10 additional seconds of wet mixing maximized the Marshall Stability of the paving mix.

The Gilsonite can be stored in an additional silo at the pug mill and sprayed into the mixer.

Gilsonite would be handled in this same manner. A screw feeder or vane feeder that measures out the amount of Gilsonite per batch can be calibrated to measure the dosage level of Gilsonite per batch. Afterward, the only residue left behind in the silo will be Gilsonite powder that can be easily cleaned out.

Gilsonite or "natural Asphalt" Mixing Process – Meltable Bags

It may be much easier to pre-package Gilsonite into small, polyethylene bags with a measured amount of Gilsonite and toss them onto the hot aggregate in a batch plant. The sidewall thickness of the bag should be about 2 mils (0.005 cm). The aggregate temperature should be around 180°C. It is the aggregate temperature that is melting the bags and the Gilsonite, not the heat from the bitumen. Therefore a temperature of 150-165°C entering the pug mill is acceptable, as long as the aggregate is sufficiently heated.

In either case, spraying Gilsonite onto aggregate or tossing bags into the pug mill, we conservatively recommend increasing the mixing time an extra 15 seconds. This will insure the Gilsonite is melted properly and dissolving into the bitumen. Finally, it is possible to just scoop or shovel a precise number of kilos of Gilsonite per batch onto the hot aggregate, no re-packaging just hand labor.

The below figure shows a cross section view of the pug mill and shows the system that Gilsonite storage is at the pug mill, and a weigh bin controls the amount of Gilsonite added to the mixer.

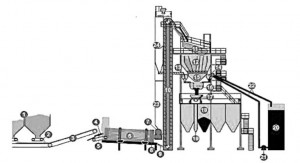

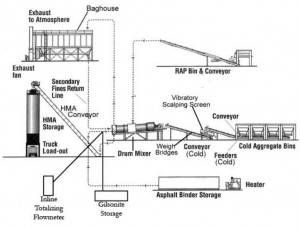

Gilsonite or "natural Asphalt" Mixing Process – Continuous Plant (Drum) Mixing

Gilsonite may be introduced into a via a screw auger. It should be added at a point inside the drum where the bitumen is added. The screw auger should be controlled by a drive motor that is calibrated to the plant’s production rate. The auger should enter the drum at the opposite end from the flame. Care should be taken to insure that Gilsonite is not caught up in the air stream and delivered to the bag house. It should be added right under the bitumen output so that a part of the Gilsonite is taken down by the bitumen to mix with the aggregate.

As it’s seen in the diagram, Gilsonite incorporated into the drum by a feed line that must be equipped with an in-line blending system capable of metering the Gilsonite within plus or minus 10 percent of the amount specified. Considering the fallowing instructions is necessary:

Interlock the metering device with the asphalt binder control equipment in such a manner as to automatically vary the Gilsonite feed rate to maintain the required proportions and which will automatically indicate in the plant control room when the flow is obstructed or stops.

Inject the Gilsonite into the asphalt binder feed line prior to introduction into the aggregate. Equip the feed line with a blending device to thoroughly mix the Gilsonite with the asphalt binder prior to mixing with the aggregate.

Provide a system capable of being calibrated, checked and monitored for accuracy and quantity of the amount used. The in-line blending system will be equipped with an in-line totalizing flow meter.

Gilsonite or "natural Asphalt" Mixing Process – Paving Procedures

Gilsonite may be introduced into a continuous mixing plant via a screw auger. It should be added at a point inside the drum where the bitumen is added. A drive motor that is calibrated to the plant’s production rate should control the screw auger. The auger should enter the drum at the opposite end from the flame. Care should be taken to insure that Gilsonite is not caught up in the air stream and delivered to the bag house. It should be added right under the bitumen output so that a part of the Gilsonite is taken down by the bitumen to mix with the aggregate.

It is not to be recommended any special paving procedure just because Gilsonite has been added to the paving mix. After modification with gilsonite, the final bitumen will have a significantly lowered penetration, a significantly increased viscosity, and a moderately increased softening point. Gilsonite modification creates a highly stable, easily workable paving mix. It is generally recommended to follow normal paving procedures and normal lay-down temperatures. If the increase in viscosity resulting from Gilsonite modification presents any flowability problems, we recommend the contractor operates at the higher end of his normal operating lay-down temperature range.

During cold weather, 5 to 10°C, gilsonite-modified mixes may tend to set-up slightly faster than standard mixes. In this case, the initial roller may follow the paver a little close and the finish roller may not have to stay back as far.